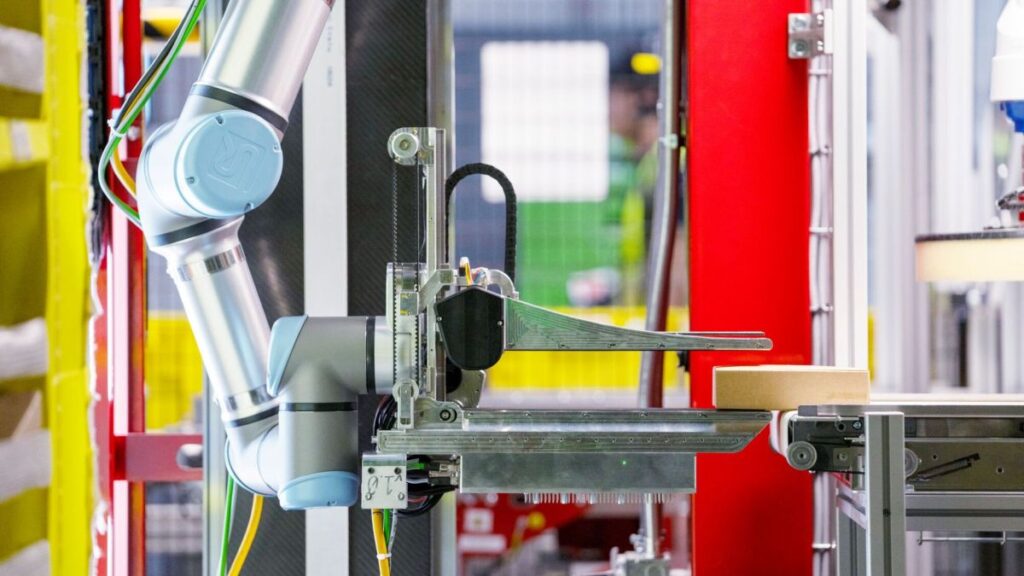

<strong>Image Credits:</strong>Amazon

Amazon Vulcan Robot: Revolutionary Warehouse Automation with Advanced Touch-Sensing Technology

Table of Contents

- Introduction to Amazon Vulcan Robot

- The Revolutionary Touch-Sensing Technology

- Technical Capabilities and Design

- Current Deployment and Performance

- Self-Improvement Capabilities

- Impact on Warehouse Operations

- Relationship with Human Workers

- Future Implications for E-Commerce Automation

- Conclusion: The Future of Warehouse Robotics

Amazon’s innovative Vulcan robot features dual arms and advanced touch-sensing technology to handle warehouse items with unprecedented precision. (Image: Amazon)

Introduction to Amazon Vulcan Robot

In a landmark development for warehouse automation technology, Amazon has unveiled its latest innovation: the Vulcan robot, a sophisticated machine equipped with the remarkable ability to “feel” the items it handles. This breakthrough represents a significant evolution in Amazon’s robotics arsenal, potentially transforming how products are processed in fulfillment centers worldwide. The Amazon Vulcan robot marks a pivotal advancement in bringing human-like sensory capabilities to automated warehouse systems.

As e-commerce continues to expand at an unprecedented rate, companies like Amazon are increasingly turning to advanced robotics to enhance operational efficiency. The Vulcan robot stands at the forefront of this technological revolution, combining precise mechanical operation with sensory feedback systems that mimic human touch—a capability that has long been considered one of the most challenging aspects of robotics to replicate.

The Revolutionary Touch-Sensing Technology

What sets the Amazon Vulcan robot apart from conventional warehouse automation systems is its innovative touch-sensing technology. The robot incorporates sophisticated force sensors that provide real-time feedback when it makes contact with objects, enabling it to detect and respond to the physical properties of items with remarkable precision. This technology allows Vulcan to handle products with varying shapes, sizes, and fragility levels—a capability that traditional robots often lack.

The Power of Touch in Robotics

The integration of touch-sensing capabilities in the Amazon Vulcan robot represents a significant breakthrough in warehouse automation. By mimicking human tactile perception, Vulcan can handle a diverse range of products with appropriate force, substantially reducing damage risks while increasing processing speed. This sensory dimension transforms how robots interact with physical objects in warehouse environments.

The force sensors implemented in the Vulcan robot provide crucial data about object weight, resistance, and positioning. This sensory information is processed in real-time, allowing the robot to adjust its grip strength and movement patterns accordingly. For instance, when handling fragile items, Vulcan can detect the minimal force needed to securely grasp the object without causing damage—a level of finesse previously achievable only by human workers.

Technical Capabilities and Design

The Amazon Vulcan robot features a sophisticated dual-arm design optimized for maximum efficiency in warehouse environments. Each arm serves a distinct purpose in the item handling process: one arm specializes in rearranging items within storage compartments, creating optimal access paths, while the second arm—equipped with an integrated camera and suction cup mechanism—precisely identifies and retrieves specific items.

This dual-arm configuration allows the Vulcan robot to manage multiple aspects of warehouse operations simultaneously. The rearrangement arm can organize products efficiently within storage pods, while the retrieval arm can locate and extract specific items for order fulfillment. The coordination between these two mechanical appendages significantly enhances processing speed and accuracy compared to single-arm robotic systems.

| Amazon Vulcan Robot Technical Specifications | |

|---|---|

| Feature | Description |

| Arm Configuration | Dual-arm system (organization arm + retrieval arm) |

| Sensory System | Advanced force sensors with touch feedback capability |

| Vision System | Integrated camera on retrieval arm |

| Gripping Mechanism | Suction cup with variable pressure control |

| AI Capabilities | Self-improvement algorithms based on operational data |

| Item Compatibility | Approximately 75% of Amazon’s inventory items |

The integration of visual and tactile sensing technologies allows Vulcan to make intelligent decisions about how to approach and handle different types of merchandise. The camera provides spatial awareness and item identification, while the force sensors deliver crucial feedback about physical contact. This sensory fusion enables a level of dexterity and adaptability previously unattainable in warehouse robotics.

Current Deployment and Performance

Amazon has strategically deployed the Vulcan robot in select fulfillment centers to evaluate its performance in real-world operating conditions. Currently, these advanced robots are actively functioning in facilities located in Spokane, Washington, and Hamburg, Germany—two key logistics hubs in Amazon’s global distribution network. These locations serve as proving grounds for the technology before potential wider implementation.

The performance metrics from these initial deployments have been impressive. According to Amazon, the Vulcan robots have collectively processed over half a million orders to date, demonstrating their reliability and efficiency in high-volume warehouse environments. This substantial order volume provides valuable data for further refinement of the technology while confirming its viability for large-scale operations.

Deployment Results

- Successfully processed 500,000+ orders across test facilities

- Operating in strategic locations: Spokane, Washington and Hamburg, Germany

- Demonstrated compatibility with approximately 75% of Amazon’s diverse inventory

- Continuously gathering operational data for system optimization

The deployment in these geographically diverse locations allows Amazon to evaluate Vulcan’s performance under different operational conditions, regulatory frameworks, and supply chain configurations. This multi-site testing approach provides comprehensive insights into the robot’s adaptability and highlights areas for potential improvement before expanding deployment to additional facilities.

Self-Improvement Capabilities

One of the most remarkable aspects of the Amazon Vulcan robot is its capacity for self-improvement through machine learning. The robot has been trained on extensive physical data, including force measurements and touch feedback patterns from thousands of interactions with different products. This training enables Vulcan to handle approximately 75% of Amazon’s diverse inventory—an impressive coverage rate for automated systems.

Beyond its initial training, Vulcan continues to learn and adapt based on its operational experiences. Each successful or unsuccessful item interaction contributes to its growing knowledge base, allowing the system to refine its approaches and handling techniques over time. This ongoing learning process means that Vulcan becomes increasingly efficient and versatile with continued use.

The Learning Advantage

The self-improvement capability of the Amazon Vulcan robot represents a significant competitive advantage in warehouse automation. Unlike fixed-function robots that require manual reprogramming, Vulcan’s adaptive learning system continuously optimizes its performance based on operational data. This results in steadily improving efficiency, reduced error rates, and expanding item compatibility over time.

The machine learning algorithms powering Vulcan analyze patterns in successful item manipulations and failed attempts, identifying optimal approaches for different product categories. This adaptive intelligence allows the robot to develop specialized handling techniques for challenging items like soft packaging, irregular shapes, or delicate products—areas where traditional robotics often struggle.

Impact on Warehouse Operations

The integration of the Amazon Vulcan robot into fulfillment center operations promises significant improvements in several key performance areas. With its advanced sensing capabilities and dual-arm design, Vulcan can process orders more efficiently than many conventional automated systems, potentially reducing processing times and increasing throughput across warehouse operations.

Additionally, the touch-sensing technology enables Vulcan to handle products with greater care than traditional robots, potentially reducing damage rates and associated costs. This is particularly valuable for high-value or fragile items that previously required special handling procedures. The ability to reliably process a wide range of product types with a single robotic system also simplifies warehouse operations and reduces the need for specialized handling equipment.

From a logistics perspective, the Vulcan robot enhances Amazon’s ability to optimize storage space within fulfillment centers. By efficiently organizing and accessing items within storage compartments, the robot helps maximize the utilization of valuable warehouse space while maintaining rapid retrieval capabilities—a critical balance in high-volume e-commerce operations.

Relationship with Human Workers

The deployment of advanced robots like Vulcan inevitably raises questions about the future of human employment in warehouse environments. Critics have suggested that Amazon’s substantial investments in robotics signal an intention to gradually replace human workers with automated systems. However, Amazon has consistently maintained that this is not the case.

According to Amazon, robots like Vulcan are designed to complement human workers rather than replace them. The company argues that these advanced machines primarily take on repetitive or physically demanding tasks, allowing human employees to focus on more complex, judgment-intensive activities where human capabilities still exceed robotic ones. Additionally, Amazon emphasizes that robotics technology can make warehouses safer by reducing the need for workers to perform potentially hazardous tasks.

This perspective aligns with broader industry observations that warehouse automation often leads to role transformation rather than wholesale replacement of workers. As robots handle more routine physical tasks, human roles typically evolve toward supervision, exception handling, maintenance, and customer-focused activities that benefit from human judgment and adaptability.

Future Implications for E-Commerce Automation

The development of the Amazon Vulcan robot with its touch-sensing capabilities represents more than just an incremental improvement in warehouse automation—it potentially signals a new direction for the entire e-commerce industry. As these technologies mature and become more cost-effective, they could reshape distribution strategies across the sector.

For Amazon, the successful implementation of Vulcan could provide significant competitive advantages in terms of operational efficiency, delivery speed, and inventory management. The ability to process orders more rapidly and accurately directly supports Amazon’s focus on customer satisfaction through fast, reliable deliveries. As the technology scales, these advantages could become increasingly significant in the highly competitive e-commerce landscape.

Beyond Amazon, the innovations embodied in the Vulcan robot could influence automation approaches throughout the retail and logistics industries. As touch-sensing and adaptive robotic technologies become more widely available, they could accelerate the adoption of advanced automation across supply chains, potentially transforming how products move from manufacturers to consumers.

Conclusion: The Future of Warehouse Robotics

The Amazon Vulcan robot represents a significant milestone in the evolution of warehouse automation technology. By successfully integrating touch-sensing capabilities with efficient mechanical design and self-improving AI, Amazon has created a system that bridges important gaps between human dexterity and robotic efficiency. This breakthrough could accelerate the development of increasingly sophisticated warehouse automation systems across the industry.

As Vulcan and similar technologies continue to evolve, we can expect to see further refinements in sensory capabilities, expanded item compatibility, and enhanced learning systems. These developments will likely push the boundaries of what automated systems can accomplish in complex, variable environments like fulfillment centers. The long-term implications extend beyond operational efficiency to fundamentally reshaping how supply chains function in the digital economy.

While questions about the relationship between advanced robotics and human employment will persist, the Vulcan robot illustrates how technological innovation can create new possibilities for human-machine collaboration rather than simply replacing human capabilities. The future of warehouse operations likely involves increasingly sophisticated partnerships between workers and intelligent machines, each contributing their unique strengths to create more efficient, safer, and more responsive fulfillment systems.